Sponsored by: Andean Alliance for Sustainable Development

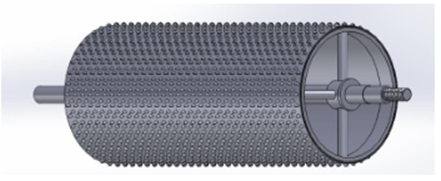

Coffee farmers in the Sacred Valley of Peru work in rural locations of the Andes Mountains where maintenance

and transportation of the final product and equipment are both time-consuming and an economic burden. The coffee harvesting process involves removing the flesh of the coffee cherry by operating a manual and labor-intensive de-pulping machine. This creates an acidic environment causing corrosion of critical components, including the camiseta. Replacing this component, along with upkeep maintenance, is conducted by a skilled machinist and requires a great amount of transportation effort as well as monetary investment.

Modify the coffee depulper to decrease maintenance, allow access to interior components for cleaning, and eliminate rusting of the camiseta. The design should result in a longer lifespan for the coffee depulper and maintain a high quality of coffee beans.

Sponsored by: Andean Alliance for Sustainable Development

Student Team:

Industry Representative: Aaron Ebner

Faculty Advisor: Brittany Nelson-Cheeseman

Pictured left to right: Christina Yang, Michael Holmes, Colin Spellman, Hannah Thatcher, Gracie Gerber