Sponsored by: 3M

You can also choose to use TommieBot, an AI search assistant developed by St. Thomas School of Engineering students and faculty.

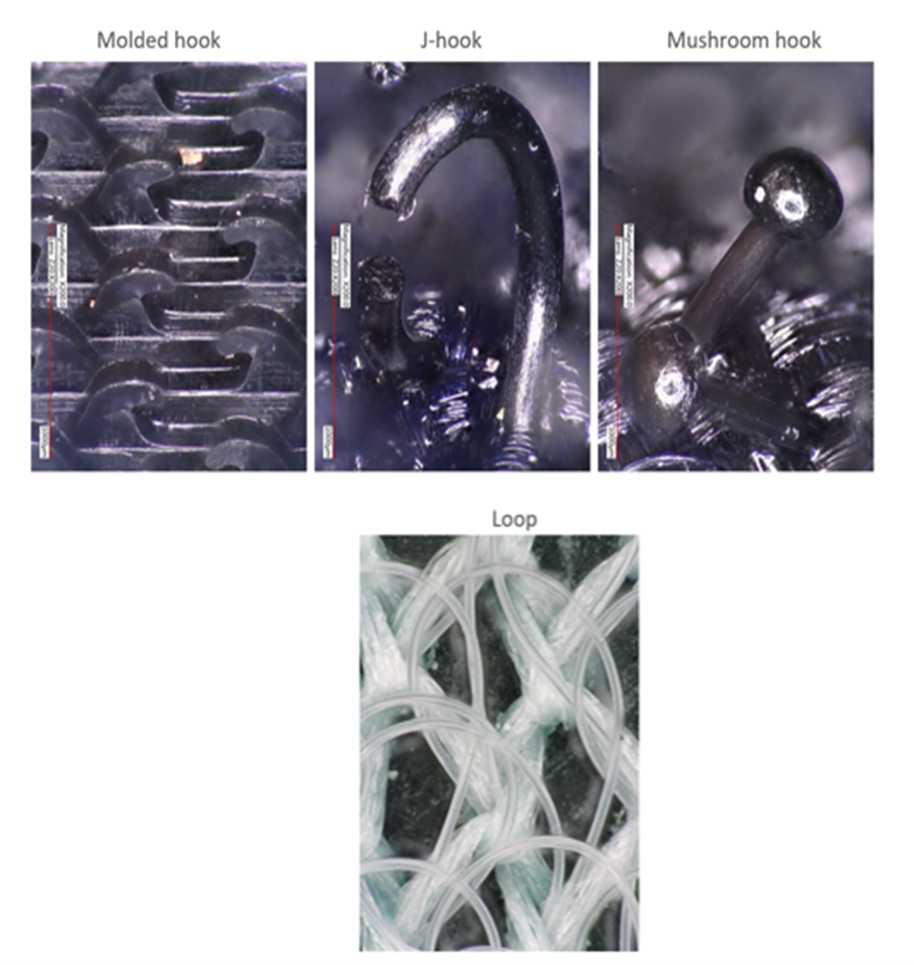

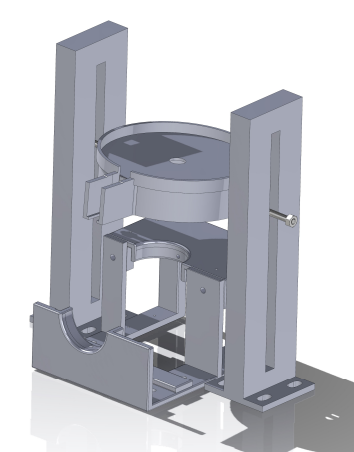

Take me to TommieBotFor optimum performance, an abrasive disc needs to firmly attach to its BUP and not move during use. Our goal is to investigate how to best measure attachment during use. In a basic hook and loop system, a DA backing pad with rigid plastic hooks attaches to a sanding disc with soft nylon loops. There are three different hook types that can be used: J-hook, mushroom, and molded. For the data, the team conducted multiple tests to arrive at conclusions on the strength, effectiveness, and durability across all three hook types. For the test method, the team designed a mounting fixture that would hold the sander in place along with an adjustable circular portion to accurately measure shift. This, coupled with the centering fixtures designed by the team, ensures accurate test results.

The team was tasked with creating a reproducible test to accurately measure shifting of the abrasive sanding disc on a dual-action sander (DA). In addition, testing was to be done to collect data on the different hook and loop combinations to understand the interaction between them and their respective properties.

Sponsored by: 3M

Student Team:

Industry Representative: Sally Lewis

Faculty Advisor: Stacha Reed

Pictured left to right: Jonathan Vue, John Scott, Mikita Lemesh, Wyatt Smith