Sponsored by: Process Logic

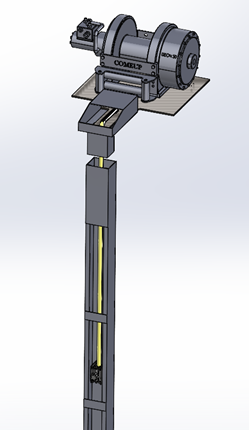

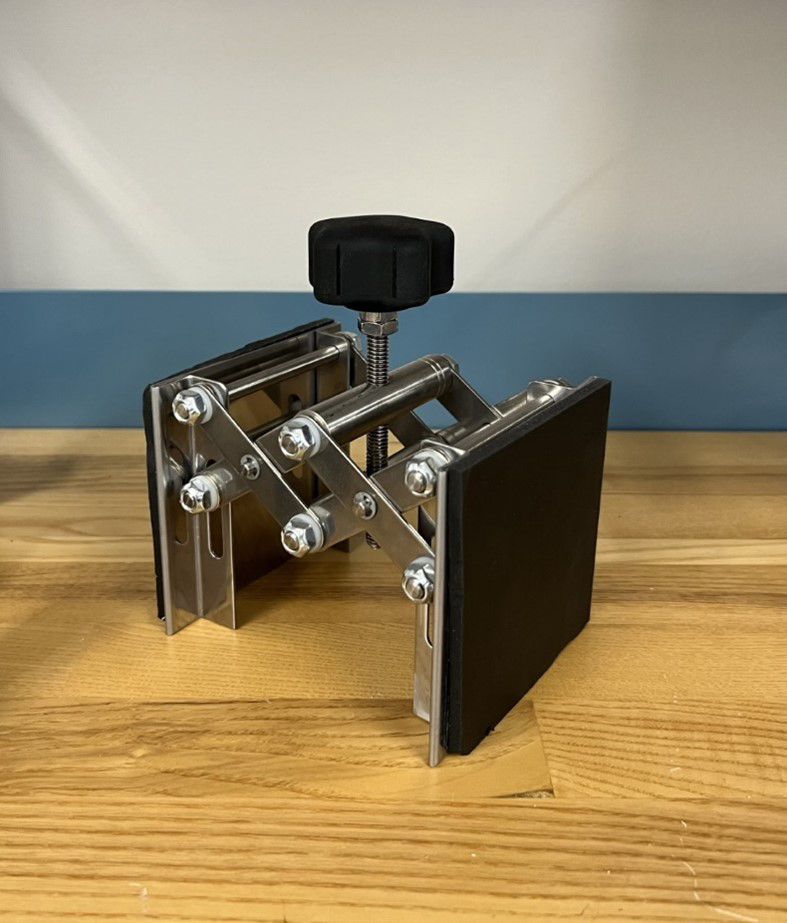

Current downspout installation practices include methods that require workers to operate using unsafe practices and positions which can cause injury or death. The current process limits the points of contact the worker would have with the ladder because they have to simultaneously hold the downspout in place while working power tools to fasten it to the building’s wall. Overall, the current process allows for a higher accident potential. This project aims to design a safer way to lift and install a downspout using a winch or similar lifting mechanism. This product would allow for the worker to maintain safer positions atop the ladder, only having to focus on fastening the downspout to the building.

Develop a mechanism that will assist in the installation of commercial downspouts so that the installation process is safer for the Process Logic employee.

Sponsored by: Process Logic

Student Team:

Industry Representative: Kurt Scepaniak

Faculty Advisor: Bob Bach

Pictured left to right: Maija Almich, Raymond Rasmussen, Charles Kiefer, Colin Huntington