Sponsored by: Safran Test Cells

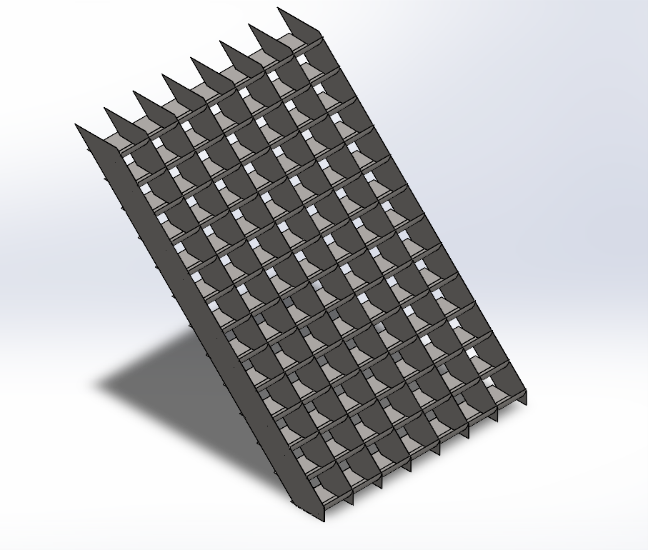

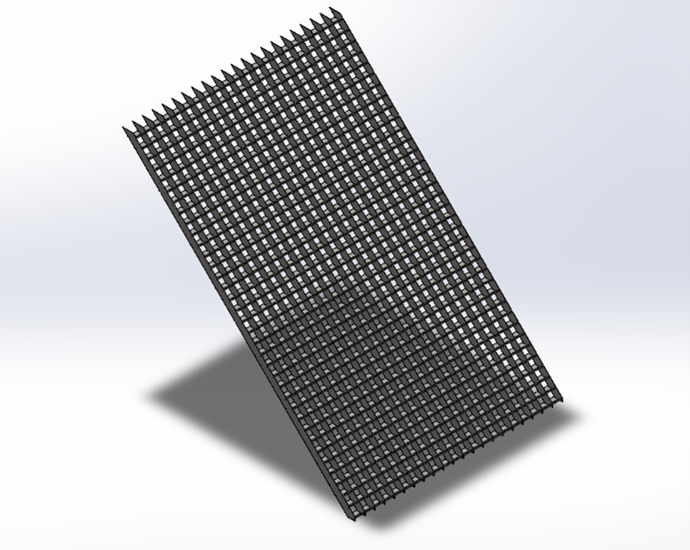

The currently used turning vane designs are from over 40 years ago and are outdated. Our team is looking for a less expensive turning vane design by reducing the amount of material needed to manufacture the turning vane. Designs were tested in ANSYS using CFD to make sure the airflow after the vanes meets the requirements set by our sponsor. Structural analysis is also required to validate that the structure can withstand the forces exerted on the newly designed turning vanes.

The design goal was to re-design turning vanes to be smaller and less expensive than the current design used by Safran.

Sponsored by: Safran Test Cells

Student Team:

Industry Representative: Steve Margl

Faculty Advisor: David Forliti

Pictured left to right: Ben Gustafson, Adrian Brietzke, Cole Halla, Alexander Bailey