Sponsored by: Partners in Food Solutions

A small and growing company in Uganda intends to process finger millet into finger millet flour and sell the flour to a large buyer that processes the flour into a nonalcoholic drinking beverage. The local millet buyer is expected to purchase substantial quantities of finger millet flour, but the quality of finger millet supplied by the company has consistently failed quality tests by the buyer on grounds of microbial loads.

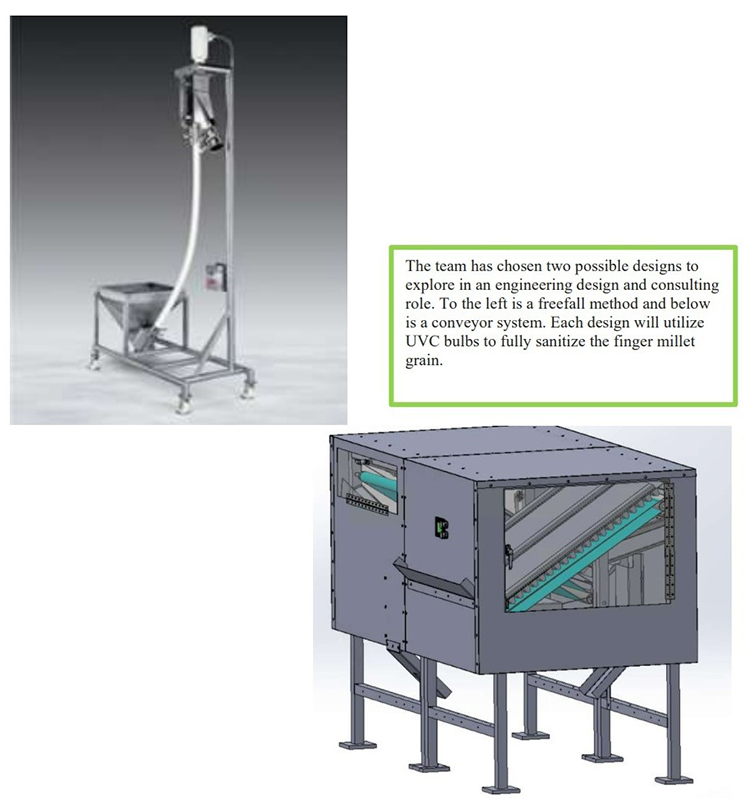

The project shall be to design prototype equipment that can subject millet to UVC lights to reduce microbial load so that the millet can pass supplier standards when the grain is tested. Designing this technology will not only create business opportunities for industries dealing in grain but also enable grain processors to have a clean and safe input of grain.

Sponsored by: Partners in Food Solutions

Student Team:

Industry Representative: Amanda Traaseth

Faculty Advisor: Robert Bach

Pictured left to right: Will Eagan, Julia Howard, Alex Jacobs, Kevyn Perkins