Sponsored by: Andersen Windows

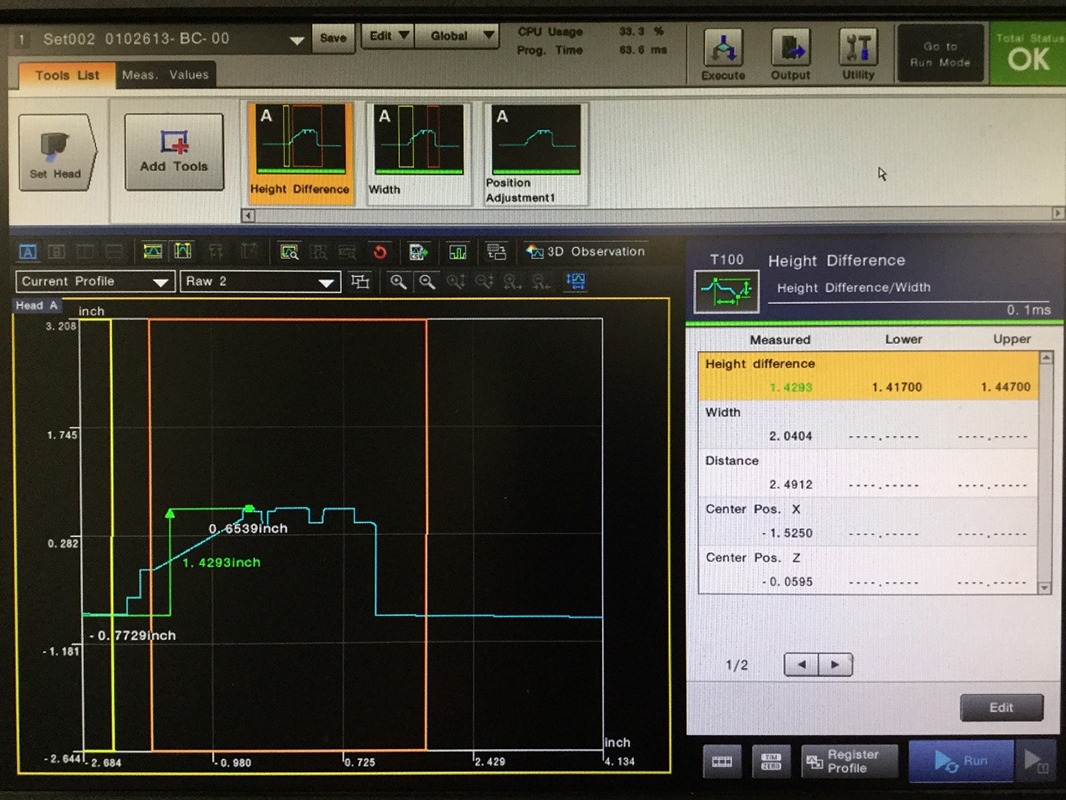

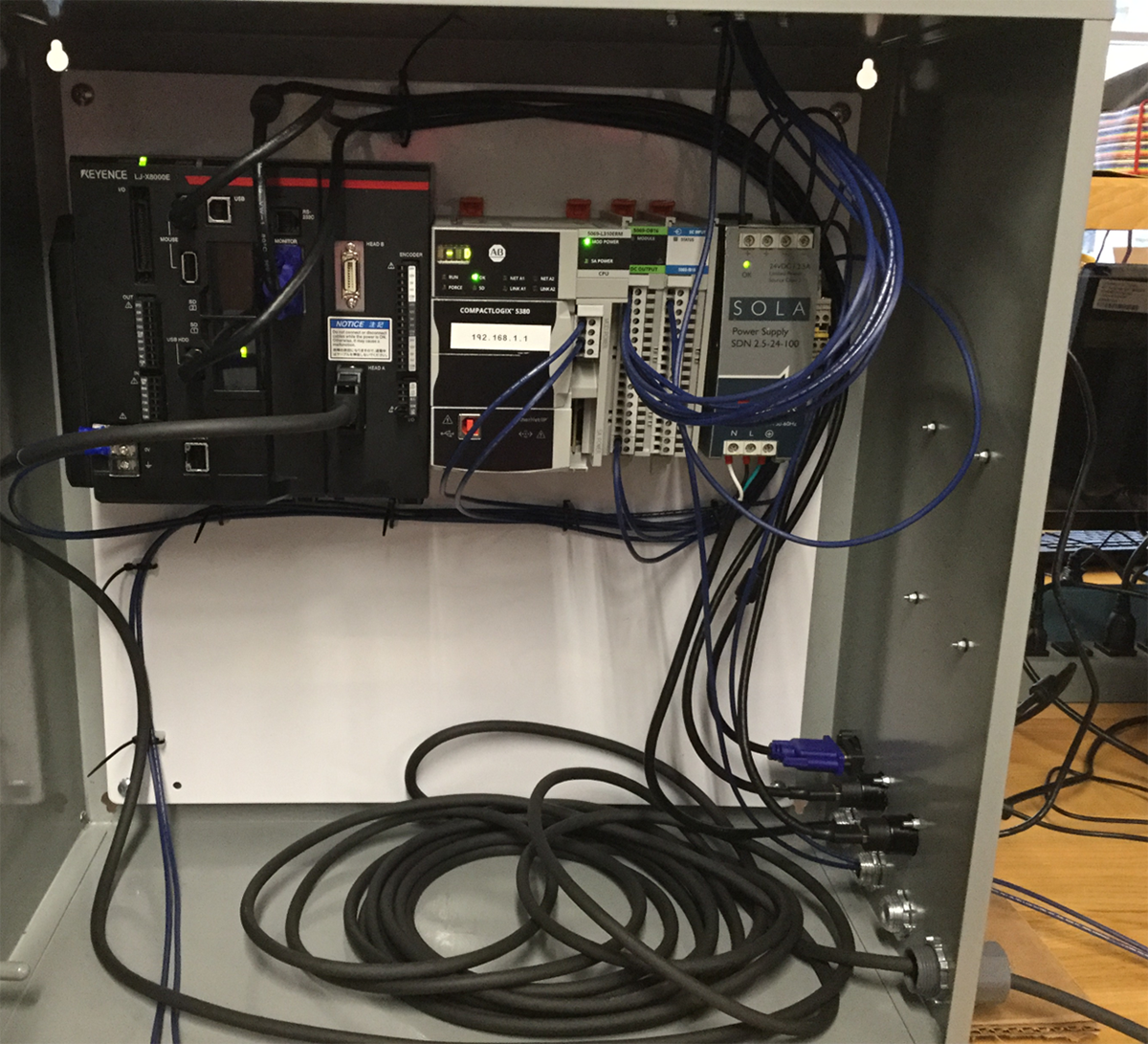

Currently on the Andersen Window moulder line there is no way to determine if a part is within specification without frequent stops to the line for the operator to manually measure the dimensions of the wood profiles. If out-of-spec parts are not caught in time, they can make it all the way to the warehouse before they are eventually found to be out-of-spec. This adds up to a lot of wasted time and wasted product. With the laser measurement system, real time data will be provided to the operator to alert them as soon as the product goes out-of-spec.

Design a system to measure wood profiles and provide a real time alert for when the parts go out-of-spec.

Sponsored by: Andersen Windows

Student Team:

Industry Representative: Matthew Carlson

Faculty Advisor: Michael Hennessey

Pictured left to right: Peter Schik, Ryan Thelen, CJ Warren, Nick DeSimone