Sponsored by: nVent - Hoffman

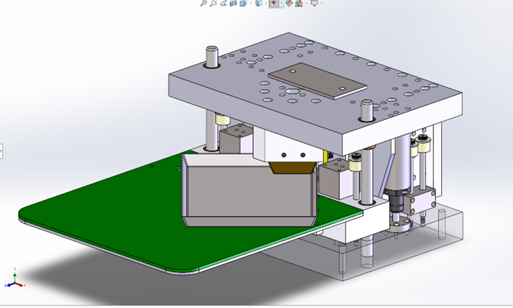

nVent HOFFMAN specializes in enclosures for electrical systems in various sizes, environments, and purposes. They are seeking a method to manufacture a new line of enclosures they are developing, which have 75° slanted corners and sides. Within the manufacturing process, they want the corner forming process to not require welding and grinding, and they succeeded in designing a tool for that task for the regular 90° door by using a hydraulic press and various mechanisms. The main goal of this project is to adapt that tool to create the corners needed in the new door design.

nVent HOFFMAN has a tool that currently bends sheet metal to form a 90° corner. The design goal of this project is to adapt that tooling to be able to form a 75° corner.

Sponsored by: nVent - Hoffman

Student Team:

Industry Representative: Scott Schramske

Faculty Advisor: Brian Plourde

Picture left to right: Tri Phan, Nate Spurgat, Valentina Pedevila, Paige Heitkamp