Sponsored by: Medtronic

You can also choose to use TommieBot, an AI search assistant developed by St. Thomas School of Engineering students and faculty.

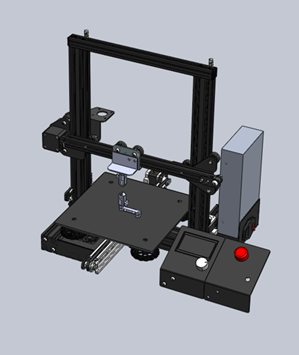

Take me to TommieBotMedical devices undergo many forces during implantation and use. It is important to be able to characterize a device’s behavior under various bending, compression, and tension forces. We will create a machine that can subject medical devices to deformation on multiple axis (X, Z, rotational), executes commands on its own, and is able to display and sync force measurements with a camera or X-Ray system. The system should also be optionally operable with no desktop computer necessary. This product is not used in testing actual medical devices but is used to characterize materials and in early development for medical devices.

This project aims to build upon another team’s design of a desktop tensile tester to be used in testing medical device packaging and parts. The deliverables include a fully functioning desktop CNC machine along with software to sync force and image measurements which can be used as a stand-alone system and operated from

a distance, outside of X-Ray housing systems.

Sponsored by: Medtronic

Student Team:

Industry Representatives: Vince Whelan, Charles Wilson and Nick Nagel

Faculty Advisor: Keith Berrier

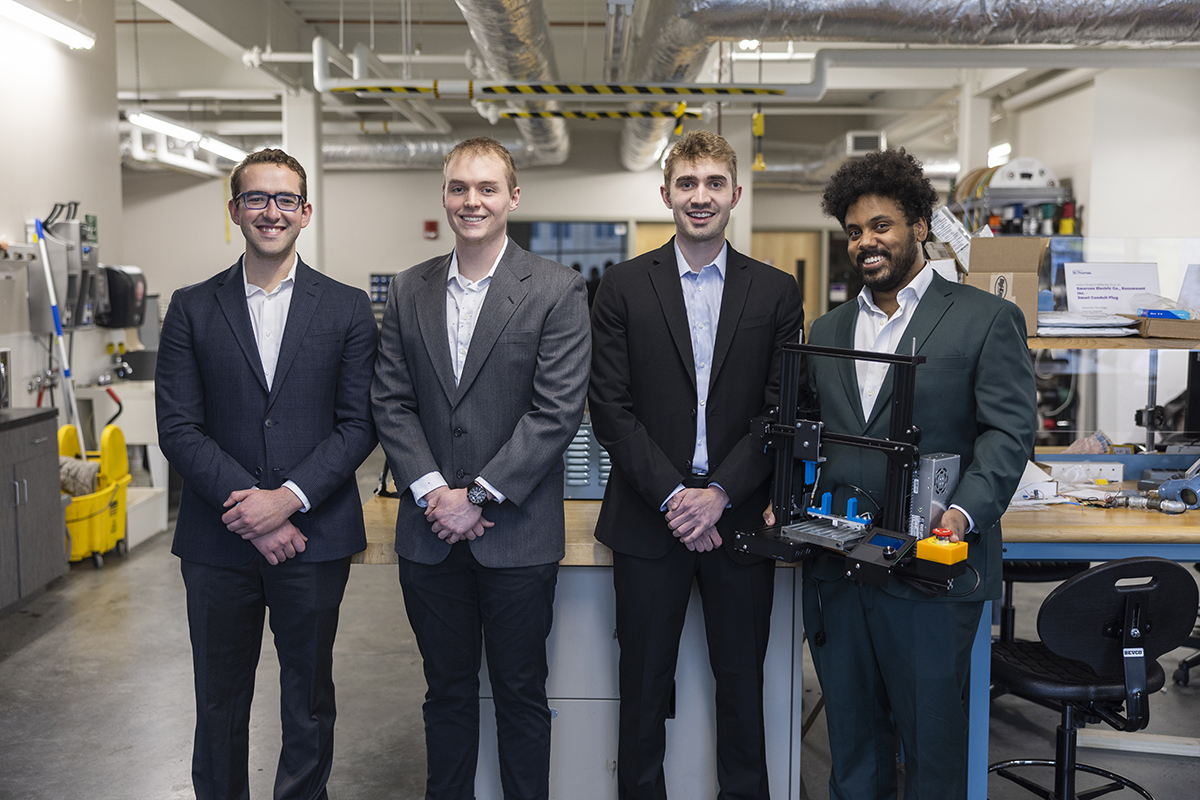

Pictured left to right: Michael Benusa, Mason Knox, Josh Johnson, Terence Lewis