Sponsored by: 3M

Heating and cooling energy to keep buildings at a comfortable temperature account for nearly 25% of the world’s total energy consumption. Low-emissivity windows allow natural light from the sun to illuminate a room, while also preventing unwanted heat from entering or leaving a given building. Low-emissivity films can be an efficient way to reduce heating and cooling energy usage without replacing an entire window. Thus, 3M has been developing low-emissivity window films to meet this need. Validating and optimizing their performance requires the creation of an environmental chamber for accurate and applicable heat flow measurements across glass/film substrates.

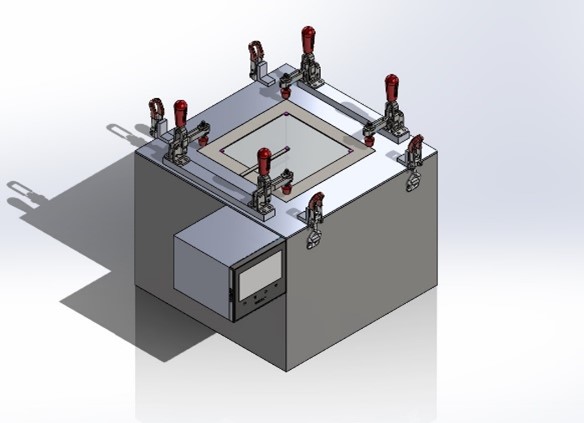

Our goal is to create a chamber that will allow for accurate and repeatable experiments to test insulating performance of the low emissivity films and treatments. A test method that will allow operators to produce precise and reproducible results will also be created.

Sponsored by: 3M

Student Team:

Industry Representatives: Greg King and Adam Readinger

Faculty Advisor: Patrick Willoughby

Pictured left to right: John Larson, Matthew Brodeur, Hyunoh Bae, Harris Anderson