Sponsored by: KEB America Inc.

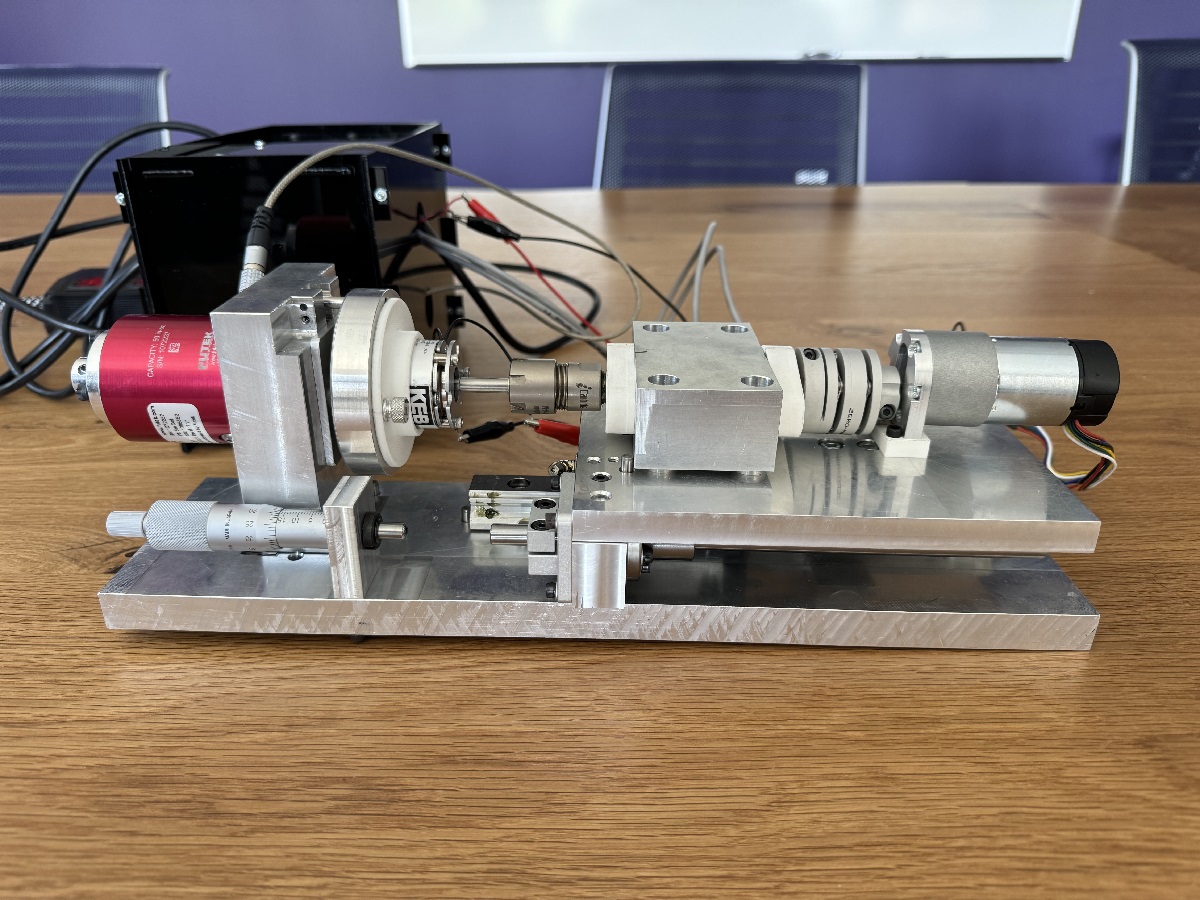

KEB America is a premier manufacturer for custom electromechanical brakes used in surgical robotics and other medical equipment. KEB’s next generation of small form factor designs require an equally small form factor test machine capable of measuring precise torque to fully characterize these new brakes. The team at UST has developed a new automated test device to support this need. Key features for this new tester include simple brake installation, flexible software, and precision torque measurement with a transducer.

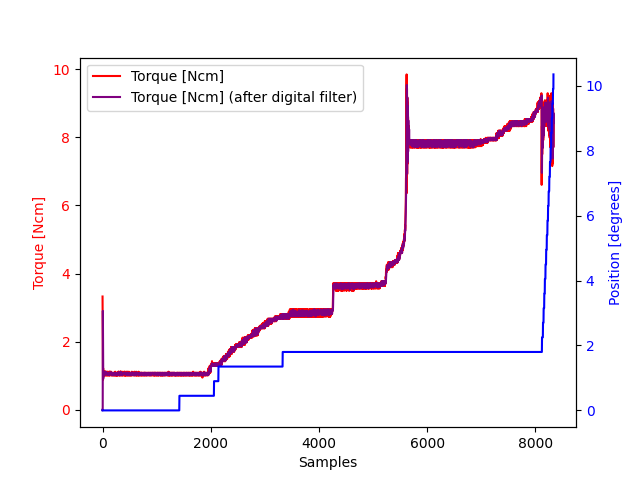

The new test system accepts smaller brakes and tests accurately at lower torques. The system first wears in the brakes to remove any surface imperfections. After this, a static test checks how much torque the brake can take before it slips. The system allows the user to enter parameters for how the test is run and what is considered pass or fail in a custom application on the user’s computer, which communicates over a network to the test system and displays the results after the test.

Sponsored by: KEB America Inc.

Student Team:

Industry Representative: Andrew Sanchez

Faculty Advisor: Farshad Esnaashari

Pictured left to right: Cam Vidlund, Abe Stroschein, Sean Sticha, Luke Terris