Sponsored by: Renewal by Andersen

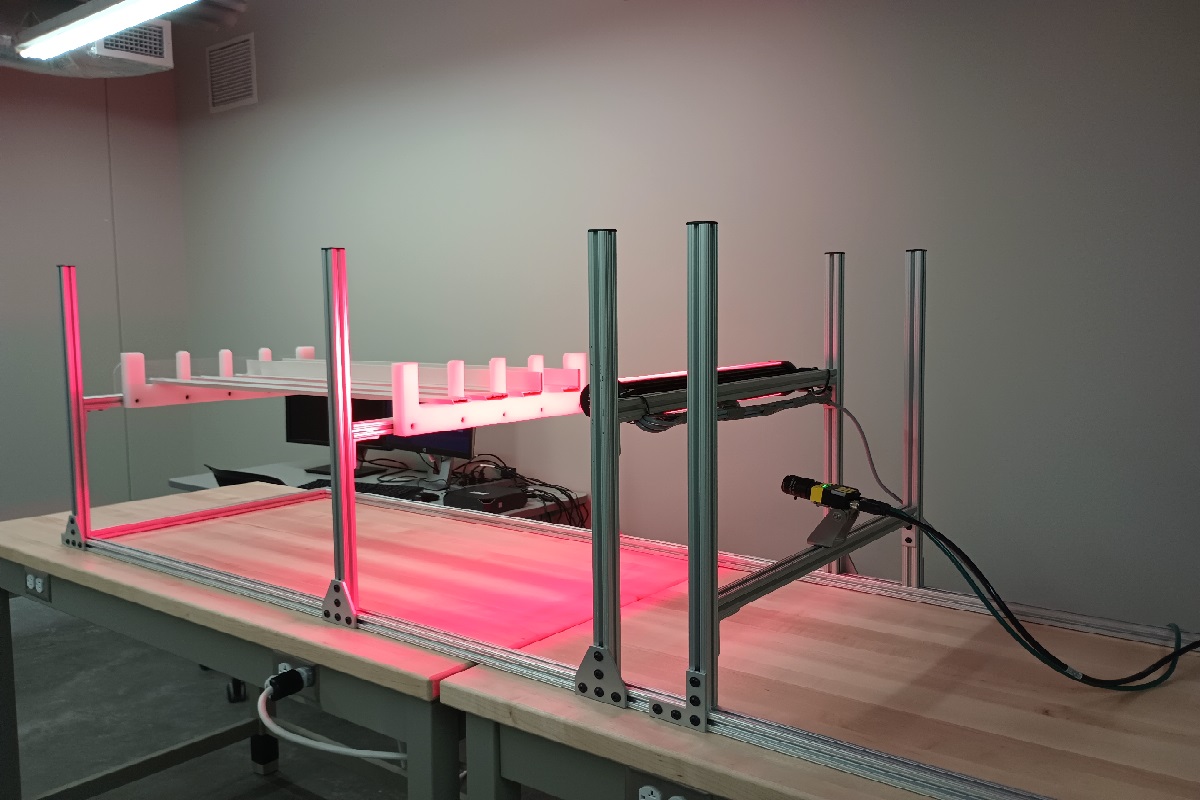

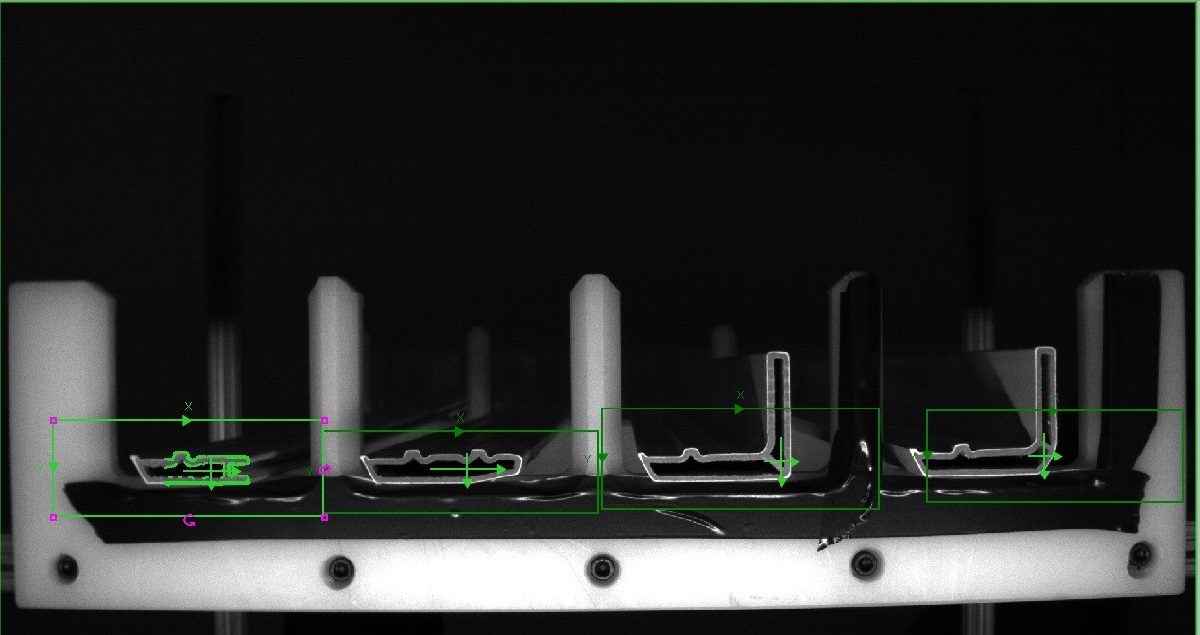

Renewal by Andersen uses automated saws to cut Fibrex stock for construction of their windows. When operators load the wrong material into the saw line, material is wasted and cannot be used. This project will focus on designing and implementing a vision based system that can identify the Fibrex stock in the saw line and alert the operators if the wrong material is loaded.

The goal of the completed vision system is to detect incorrectly loaded stock in Renewal by Andersen’s saw line. This will prevent wasted time and materials in the window manufacturing process.

Sponsored by: Renewal by Andersen

Student Team:

Industry Representative: Jason Pimlott and Danielle Gross

Faculty Advisor: Gary Jing

Pictured left to right: : Max Redfearn, Carter Kyllo, Nathan LoPresto, Tyler Wenger, Jack Gables.