Sponsored by: Safran Test Cells

You can also choose to use TommieBot, an AI search assistant developed by St. Thomas School of Engineering students and faculty.

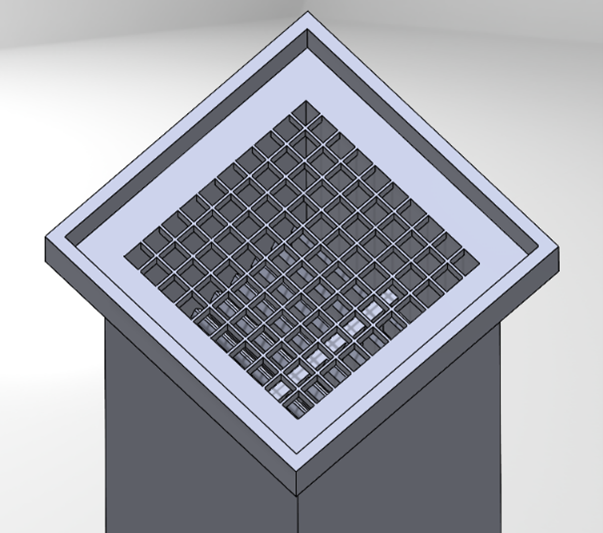

Take me to TommieBotSafran is a company that builds and sells Jet engine test cells. These test cells are used to simulate real life operating conditions for jet engines before they are mounted to their airframes. This project’s focus is on improving the distribution of airflow through finding modifications to the inlet stack of the Jet engine test cell. The components that can be modified include a stainless steel egg crate structure in addition to the exterior building structure itself.

Find a way to adjust the current design of the 9m by 9m cross section inlet stack of a jet engine test cell that reduces the effect of cross-wind on the uniformity of the airflow downstream (near the actual testing area for the jet engine). The design should improve the uniformity of airflow while also reducing the material used in the stainless steel egg crate. Additionally, the design must allow for easy inspection and maintenance access to ensure component safety regularly.

Sponsored by: Safran Test Cells

Student Team:

Industry Representative: Steve Margl

Faculty Advisor: David Forliti

Pictured left to right: Isaac Oleson, Zach Paulson, Henry Claridge, Adam Johnson