Sponsored by: Solventum (formerly 3M Health Care)

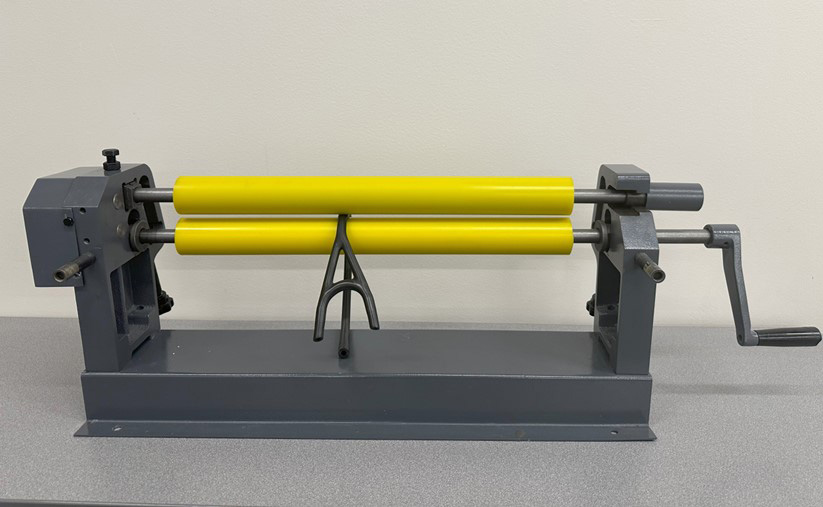

Solventum produces the Littmann line of stethoscopes, which are used in everyday clinical settings by healthcare professionals. Our senior design team was tasked with designing a process that improves the appearance of the Littmann stethoscope tubing. This process involves surface modification of the tubing through compression by a slip roller mechanism. This mechanism transforms the tubing from a glossy surface finish to a uniform matte surface finish without damaging the tubing. The final goal of this mechanism is to produce consistent and ready-for market stethoscope tubing that satisfies the needs of healthcare professionals.

Design and prototype a mechanism with a CAD drawing that produces the desired surface finish for Solventum’s Littmann Stethoscope.

Sponsored by: Solventum (formerly 3M Health Care)

Adjustable Parameters:

Student Team:

Industry Representatives: Jeffrey Pederson, Zane Johnson, Del Lawson, Dylan Cosgrove and Craig Conti

Faculty Advisor: Keith Berrier

Pictured left to right: Paris O’Reilly, Connor Miller, Zachary Maaske, Bridget Hill, Rabia Malik