Sponsored by: Trane Technologies

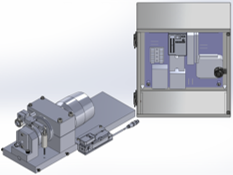

In an effort to extend the lifespan of Heating Ventilation and Cooling (HVAC) systems and meet new energy efficiency targets, Trane Technologies and the University of St. Thomas are seeking to develop an advanced wear simulator capable of characterizing candidate materials for compressor bearing applications based on their performance in a rigorous wear testing process. The test apparatus must simulate HVAC operating conditions. By doing so, the apparatus will enable faster material selection, ultimately reducing the time to market for new products.

Current material characterization test methods are limited to low operating speeds and don’t reflect the operating conditions a compressor bearing experiences in an HVAC system. The custom designed test apparatus will enable Trane Technologies to conduct accelerated wear testing that mimics the wear a compressor bearing experiences while in operation.

Sponsored by: Trane Technologies

Student Team:

Industry Representative: Wasim Akram

Faculty Advisor: Raymond Haremza

Pictured left to right: Joel Rodich, Matt Murphy, David Grant, Sam Jacobson