Sponsored by: Twin Cities Fan Companies, Ltd.

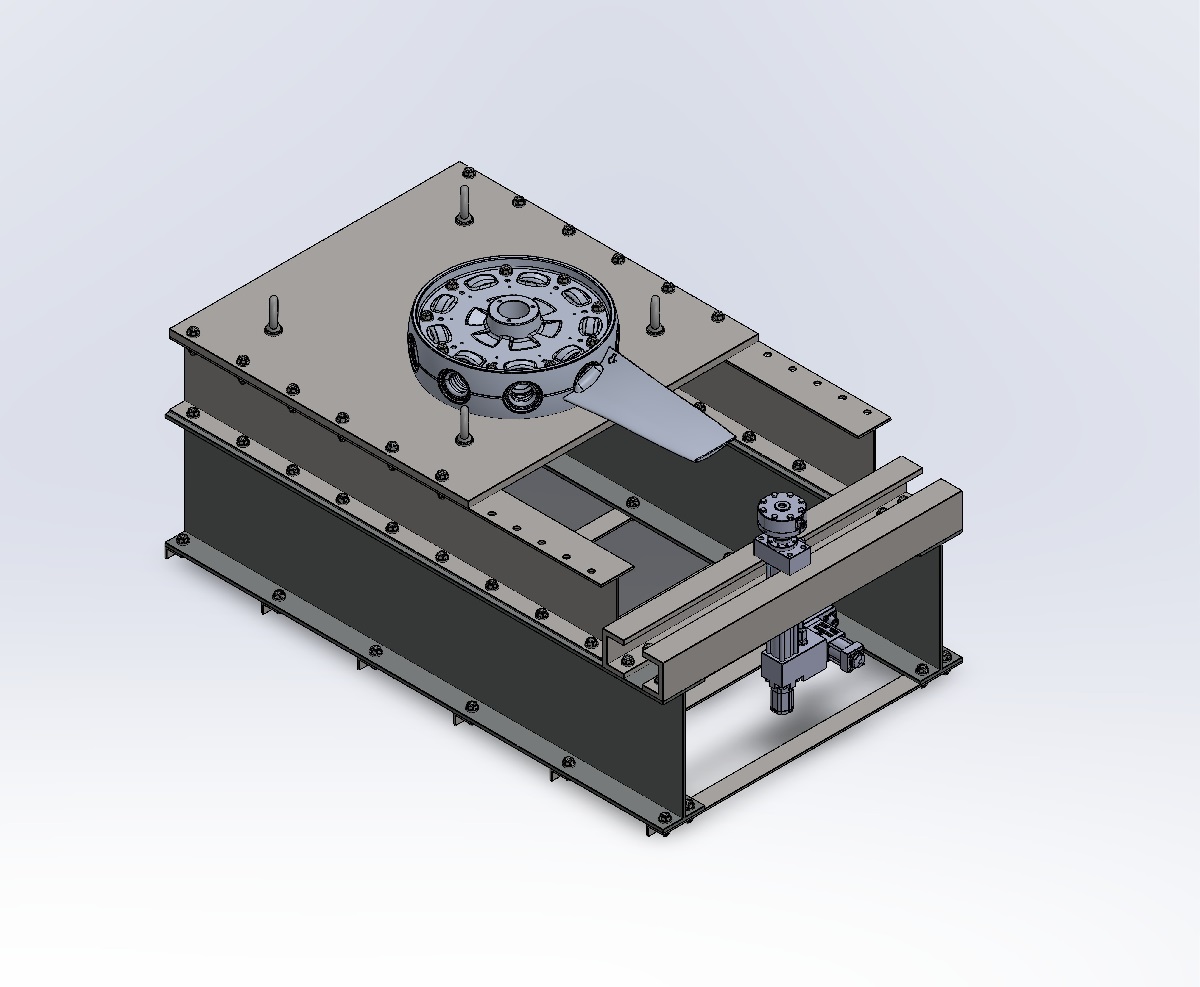

This project aims to develop an automated test stand for Twin City Fan to evaluate the fatigue life and material properties of their axial fan blades. The primary objective is to design and prototype a machine that can apply adjustable sinusoidal loading perpendicular to the fan blades, mimicking turbulent airflow conditions. The system will measure blade deformations, vibrations, and stress over a high number of loading cycles, generating empirical data to validate and refine Twin City Fan's computational models for blade fatigue analysis. By correlating physical testing results with simulations, the improved models will enable optimized blade designs, reducing reliance on costly prototypes and ensuring product longevity and reliability.

Our overall goal is to create a proof-of-concept prototype structure that can apply and withstand the forces required to perform a fatigue test and fit each size of hub/blade assembly that TCF has to offer. Along with this, design a safety device to shield users from potential injuries.

Sponsored by: Twin Cities Fan Companies, Ltd.

Student Team:

Industry Representatives: Chi Tang and Kyle Brownell

Faculty Advisor: Bob Bach

Pictured left to right: Bjorn Eggen, Alex Roemen, Aidan Willard, Griffin Peeters