Sponsored by: 3M

You can also choose to use TommieBot, an AI search assistant developed by St. Thomas School of Engineering students and faculty.

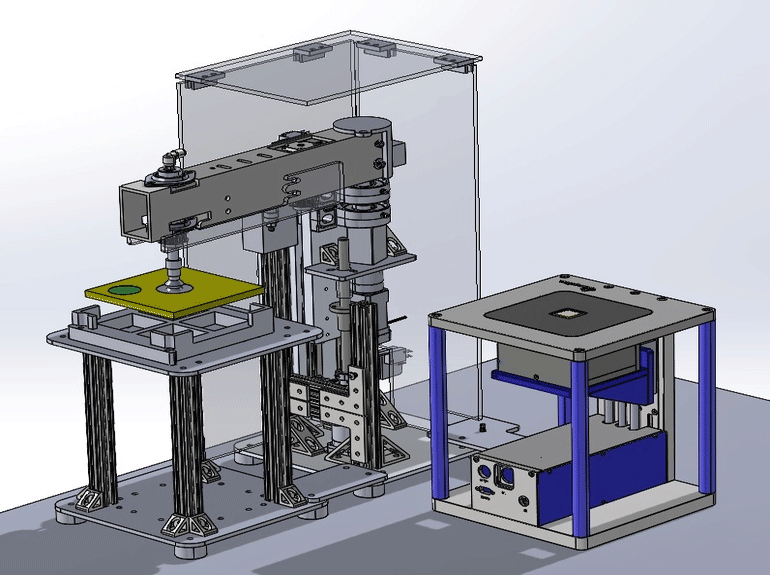

Take me to TommieBot3M Corporate Research Analytical Laboratory (CRAL) supports product developers across 3M with advanced measurements and method development. One key tool is the NMR-Mouse, a single-sided magnetic-resonance sensor with a 1 in × 1 in opening that briefly energizes hydrogen atoms in the first few millimeters of a sample using a radio pulse and then detects how that signal fades. The way the signal relaxes reflects how mobile the molecules are near the surface, which lets analysts determine moisture and how fully a material has cured (how completely a polymer or adhesive has set and hardened). The instrument is used on polymers (bulk plastic or rubber parts and adhesives), films (thin polymer sheets and coatings), and composites (layered materials such as fiber-reinforced laminates), and it does this without cutting the sample. Operators currently place each sample by hand, keep it flat, trigger the scan, wait 30 minutes to 4 hours, and remove it. Our project delivers a compact, benchtop automation system that performs this handling: a non-magnetic arm picks from a queue of ≥ 10 samples, places each piece over the opening flat at ≤ 0.5 mm clearance, triggers the scan via 5 V TTL, holds steady during measurement, and returns the sample to storage. A labeled interface provides clear status, progress, and error indications for a standing user.

Design and demonstrate a compact, non-magnetic automation system that safely places and holds flat samples over the NMR-Mouse opening, maintains the required working distance during a scan, accepts the sponsor’s range of sizes and thicknesses, interfaces with the instrument using 5 V TTL signals, and manages at least 10 queued samples with a simple, labeled interface.

Download the project summary (PDF file).

Sponsored by: 3M

Student Team:

Industry Representatives: Courtney Vander Pyl, Hattie Ring, Mark McCormick and Megan Gades

Faculty Advisor: Mahmoodi Abolghassem

Pictured left to right: Anne Martin, Mark Amundson, Peter Asamoah, Owen Mcchane